SHAFT & BEARING JOURNALS

This precisely and fully automated laser cladding process accompanied with its measurable metallurgical advantages makes it ideal for repair of components in many critical applications such as:

– Drive shafts

– Pinion shafts

– Rudder shafts

– Propeller shafts

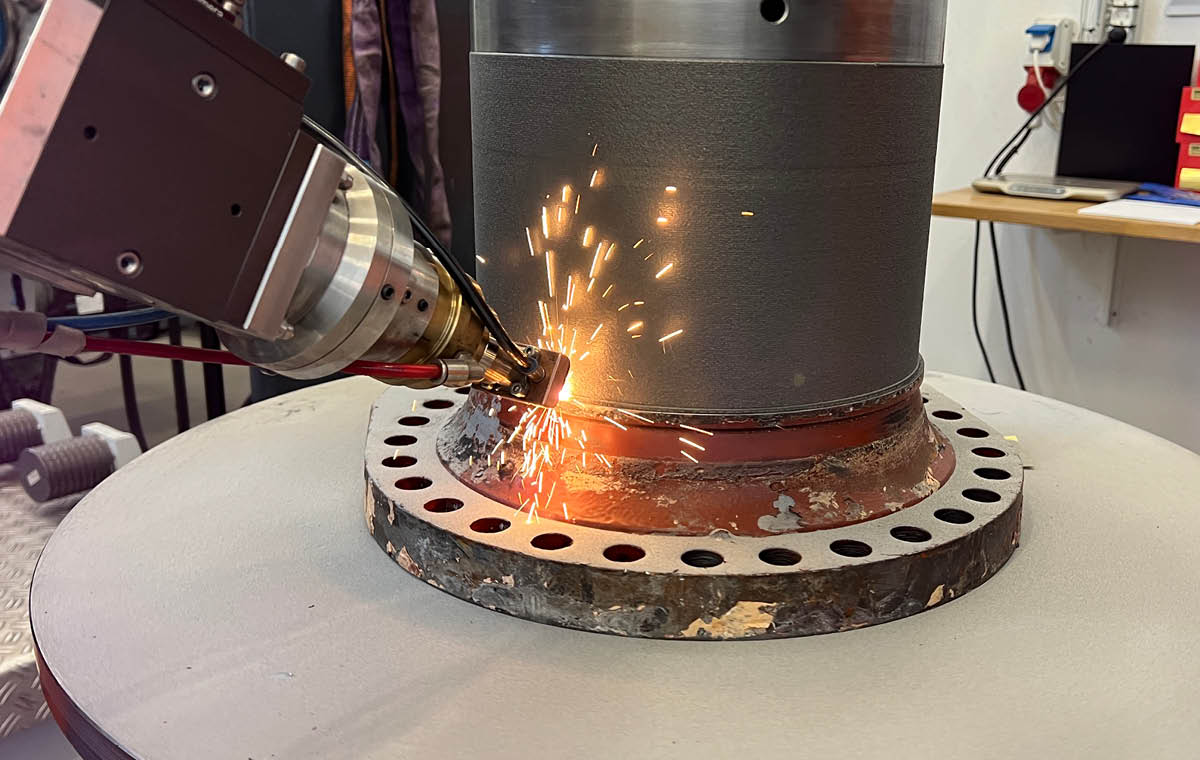

Shaft repair and recondition with Laser Powder Cladding Technology

Our innovative surface modification technique guarantees an unparalleled bond between the base material and coating material, overcoming challenges associated with traditional welding.

With low heat input and minimal dilution levels, our method offers a cost-efficient and effective approach to revitalizing turbo charger parts.

Key Features:

• Enhanced Wear Resistance: Laser powder cladding elevates wear

resistance to new levels, ensuring longevity and durability.

• Improved Corrosion Resistance: Experience superior corrosion resistance,

addressing vulnerabilities seen in conventional welding.

• Optimized Thermal Stability: Our technique enhances thermal stability, a

critical factor for performance in varied environments.

• Increased Conductivity: Benefit from improved conductivity, optimizing

the functionality of the coated components.

• Reduced Distortion and Stress Cracking: Minimize distortion and stress

cracking, ensuring structural integrity throughout the welding process.

Why Choose Our Laser Powder Cladding Facility?

• Cutting-edge Equipment: Our facility is equipped with state-of-the-art

technology, ensuring precision and efficiency.

• Expertise: Our team brings extensive expertise to every project, guaranteeing

outstanding results.

• Transformative Potential: Witness the transformative potential of laser

powdercladding in the welding industry through our exceptional outcomes.

Embark on a journey towards excellence in welding and surface engineering with us. Explore the limitless possibilities of laser powder cladding technology for welding, setting new standards for performance and durability.